MIG/MAG, MMA, TIG which welding process and for what?

We made a detailed comparison of MIG Welding and TIG Welding in the last article, and now we will compare the similarities and differences of another two welding processes under gas metal arc welding (GMAW): MIG welding VS. MAG Welding. MIG welding and MAG welding are two common types of gas metal arc welding (GMAW) that use an electric arc to melt and join metal pieces.

MIG vs Stick Welding Which is Better? (Pros & Cons)

Here are a few of the key considerations when deciding whether MIG or MAG welding is best for your needs: MAG welding is more cost-effective than MIG welding. MAG welding provides more penetrating power. MAG welding is best used on thicker, ferrous metals like steel. MIG welding is more accurate and precise than MAG welding.

WeldMart Inc. MIG vs. MAG Welding Is There a Difference? Milled

May 2020 Almost any material can be welded using common welding processes: metal inert gas or metal active gas (MIG/MAG), tungsten inert gas (TIG) or electrode (manual metal arc) welding methods. Which process to use depends on the requirements of the component and the production process.

MIG/MAG welding torches special versions and wearing parts Perfect Welding

This video covers a detailed discussion on the major differences between MIG Welding and MAG Welding.Subscribe to @AcademicGainTutorials for more Updated Vid.

What is the difference between MIG and MAG? RELONBrandMIGInverterWeldingMachine

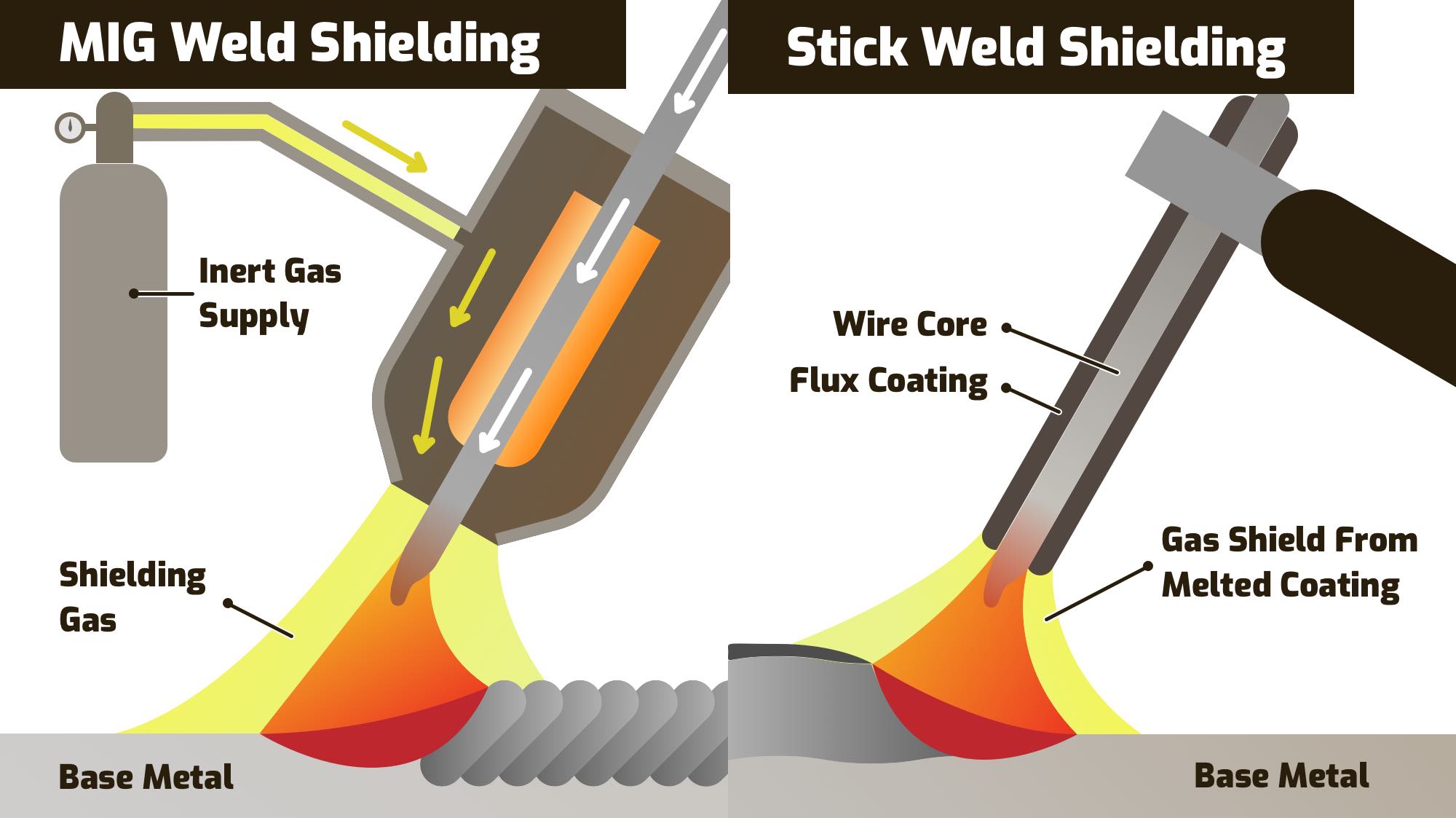

The Main Difference Between MIG and MAG Welding MIG welding and MAG welding are similar in many ways, but the biggest way they differ is in their shielding gas. In welding, the shielding gas is a gas used at the welding torch to help prevent the weld from oxidizing due to the oxygen in the surrounding atmosphere.

Diferença Solda TIG e MIG/MAG

However, MIG (metal inert gas welding) and MAG (metal active gas welding) have one significant difference — the type of used shielding gas. In this article, we'll examine the difference between the MIG and MAG welding processes and explain what each is meant for. Photo by @cirizawelding How GMAW Works in Short

MIG Vs. MAG Welding|Tooliom

The primary difference between MIG and MAG welding is their full forms. MIG is an acronym for Metal Inert Gas, while MAG stands for Metal Active Gas. The names differ in the gases used to shield the welding arc. Gas Used in Shielding the Weld. MIG welding uses inert gases, such as Helium and Argon, to shield the welding arc.

MIG vs. MAG Welding Differences & When To Use Them

Metal Inert Gas (MIG) and Metal Active Gas (MAG) welding are gas metal arc welding (GMAW) processes that use heat created from a DC electric arc between a consumable metal electrode and a workpiece which melt together to create a weld pool that fuses to form a join. Click here to see our latest technical engineering podcasts on YouTube.

MIG / MAG welding everything you need to know

The MIG and MAG welding methods differ from each other in that MIG (metal inert gas) welding uses an inert shielding gas, which does not participate in the welding process, while MAG (metal active gas) welding employs an active shielding gas that participates in the welding process.

MIG vs. MAG Welding Is There a Difference YesWelder

MIG welding, also known as Metal Inert Gas welding, is a welding process that uses inert gases like argon and helium to shield the weld puddle from atmospheric contamination. Inert gases don't chemically interact with the molten metal, so they don't influence the weld to a large extent.

MIG vs. MAG Welding Is There a Difference YesWelder

Metal Inert Gas (MIG) welding and Metal Active Gas (MAG) welding, process numbers 131 and 135 respectively in accordance with ISO 4063, are both variations of the Gas Metal Arc Welding (GMAW) process, which they are more commonly referred to as in USA and some other countries. These use heat created from an electric arc between a consumable metal electrode and a workpiece, creating a weld pool.

diferencia entre soldadura mig y mag 17 Soluciones para Diferencia Entre Soldadura Mig Y Mag

MIG uses an inert gas, while MAG uses active gasses. Both processes have some overlapping procedures and are easily adapted to robotic manufacturing. Knowing which process to use is critical to the weld quality of every project. How do you know whether to use standard MIG (GMAW) or MAG (GMAW-A)?

MIGMAG welding YouTube

Following are the differences between these processes: TIG & MIG uses Inert gases while MAG uses active gases. MIG & MAG uses solid wire spool for welding while TIG uses solid straight length (1 m) of wires. MIG-MAG has high weld deposit while TIG is a slow weld deposition process.

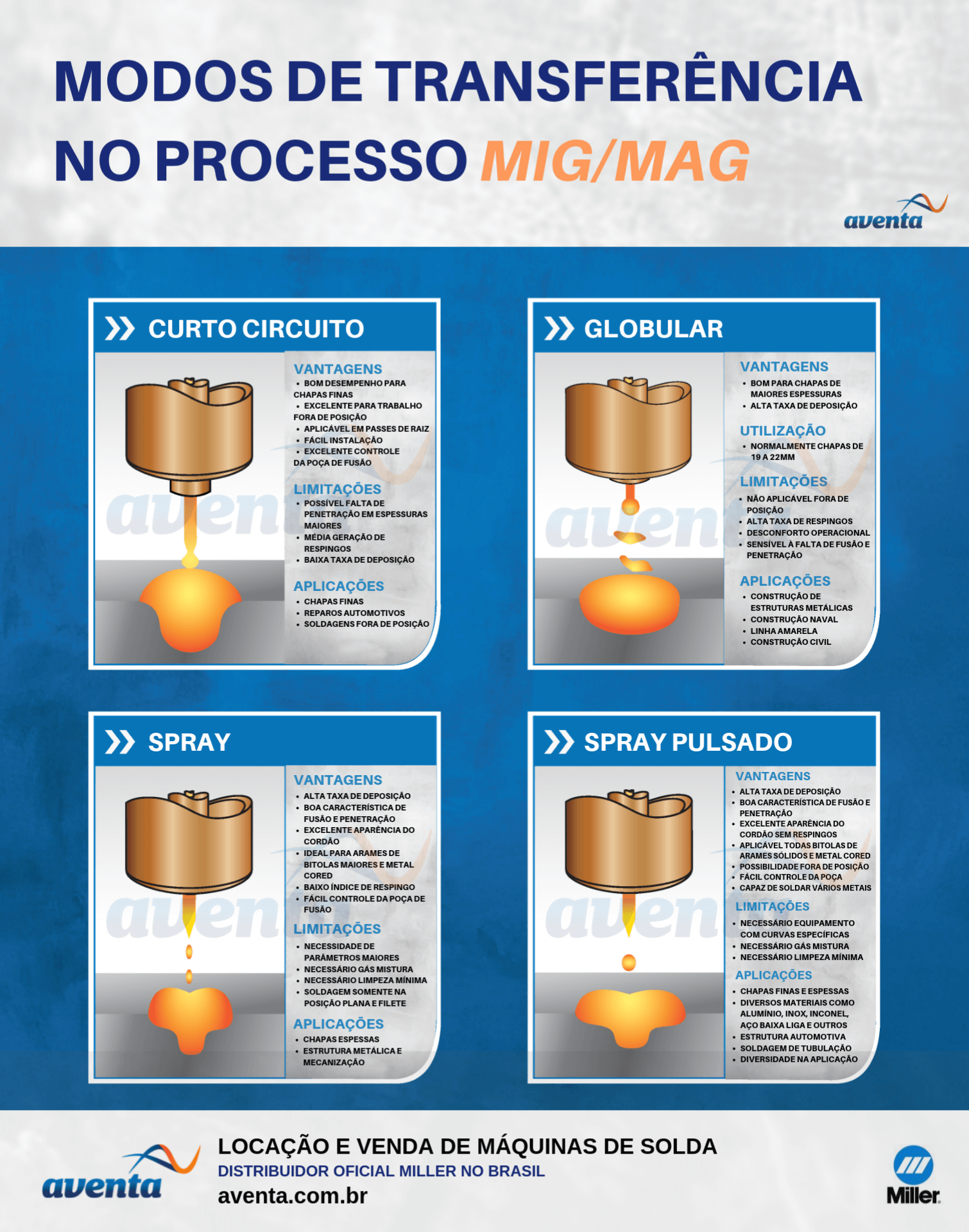

Modos de Transferênica MIG MAG (Tabela)

MIG/MAG welding is also referred to as gas metal arc welding. A differentiation is made between metal inert gas welding (MIG) and metal active gas welding (MAG). MIG/MAG is currently the most frequently used welding process and allows for particularly high welding speeds. It can be used in a manual, mechanized or robot-supported manner.

ℹ Soldadura MIG vs. Soldadura MAG Diferencia de estos dos Procesos

Metal Inert Gas (MIG) and Metal Active Gas (MAG) are two different types of GMAW processes. Shielding gas is necessary (and thus used) in both the cases; however, composition of shielding gas is different. In fact, constituent of shielding gas is primary factor for classifying GMAW process as MIG and MAG.

MIG vs MAG welding differences

MIG/MAG welding is a type of arc welding that uses a shielding gas with a consumable electrode. Both types of welding use an electrode used by a continuous wire that is protected from the atmosphere. Next, we are going to see the differences between MIG vs MAG welding.